Dissimilar Metal Welding

Welding of dissimilar metals refers to the process of welding two or more metals with different chemical compositions, metallographic structures and properties under certain process conditions.

When two different metals are welded together, a transition layer with different properties and structure from the parent material will inevitably be produced. And as there are significant differences between dissimilar metals in elemental properties, physical properties, chemical properties, etc., the welding processing is much more complicated in terms of welding mechanism and operation technology.

Difficulties:

1. The greater the difference in melting points of dissimilar materials, the more difficult it is to weld.

This is because when the material with a low melting point reaches a molten state, the material with a high melting point is still in a solid state. At this time, the molten material can easily penetrate into the grain boundary of the overheating zone, causing the loss of the low melting point material, the burning or evaporation of the alloy elements. Makes welding joints difficult to weld.

2. The greater the difference in linear expansion coefficients of dissimilar materials, the more difficult it is to weld.

The larger the linear expansion coefficient of a material, the greater its thermal expansion rate and the greater its contraction during cooling, which will produce great welding stress when the molten pool crystallizes. This welding stress is not easy to eliminate, resulting in large welding deformation. Due to the different stress states of the materials on both sides of the weld, cracks may easily appear in the weld and heat-affected zone, and even lead to peeling of the weld metal and the parent material.

3. The greater the difference in thermal conductivity and specific heat capacity of dissimilar materials, the more difficult it is to weld.

The thermal conductivity and specific heat capacity of the material will deteriorate the crystallization conditions of the weld metal, severely coarsen the grains, and affect the wetting properties of the refractory metal. Therefore, a strong heat source should be used for welding, and the position of the heat source during welding should be biased towards the side of the base material with good thermal conductivity.

4. The greater the difference in electromagnetic properties between dissimilar materials, the more difficult it is to weld.

Because the greater the difference in the electromagnetic properties of the materials, the more unstable the welding arc will be and the worse the weld will be.

5. The more intermetallic compounds are formed between dissimilar materials, the more difficult it is to weld.

Since intermetallic compounds are very brittle, they can easily cause cracks or even breakage in welds.

6. During the welding process of dissimilar materials, the performance of the welded joint deteriorates due to changes in the metallographic structure of the welding area or the newly formed structure, which brings great difficulties to welding.

The mechanical properties of the joint fusion zone and heat-affected zone are poor, especially the obvious decrease in plastic toughness. Due to the decrease in joint plasticity and the existence of welding stress, dissimilar material welded joints are prone to cracks, especially the heat affected zone is more prone to cracks and even fractures.

7. The stronger the oxidizability of dissimilar materials, the more difficult it is to weld them.

When copper and aluminum are welded by fusion welding, copper and aluminum oxides are easily formed in the molten pool. During cooling and crystallization, the oxides present at the grain boundaries can reduce the intercrystalline bonding strength.

8. When welding dissimilar materials, it is difficult for the weld and the two base metals to meet the requirements of equal strength.

This is because metal elements with low melting points are easily burned and evaporated during welding, which changes the chemical composition of the weld and reduces the mechanical properties, especially when welding dissimilar non-ferrous metals.

Advantages:

1. Enhanced Strength and Durability:

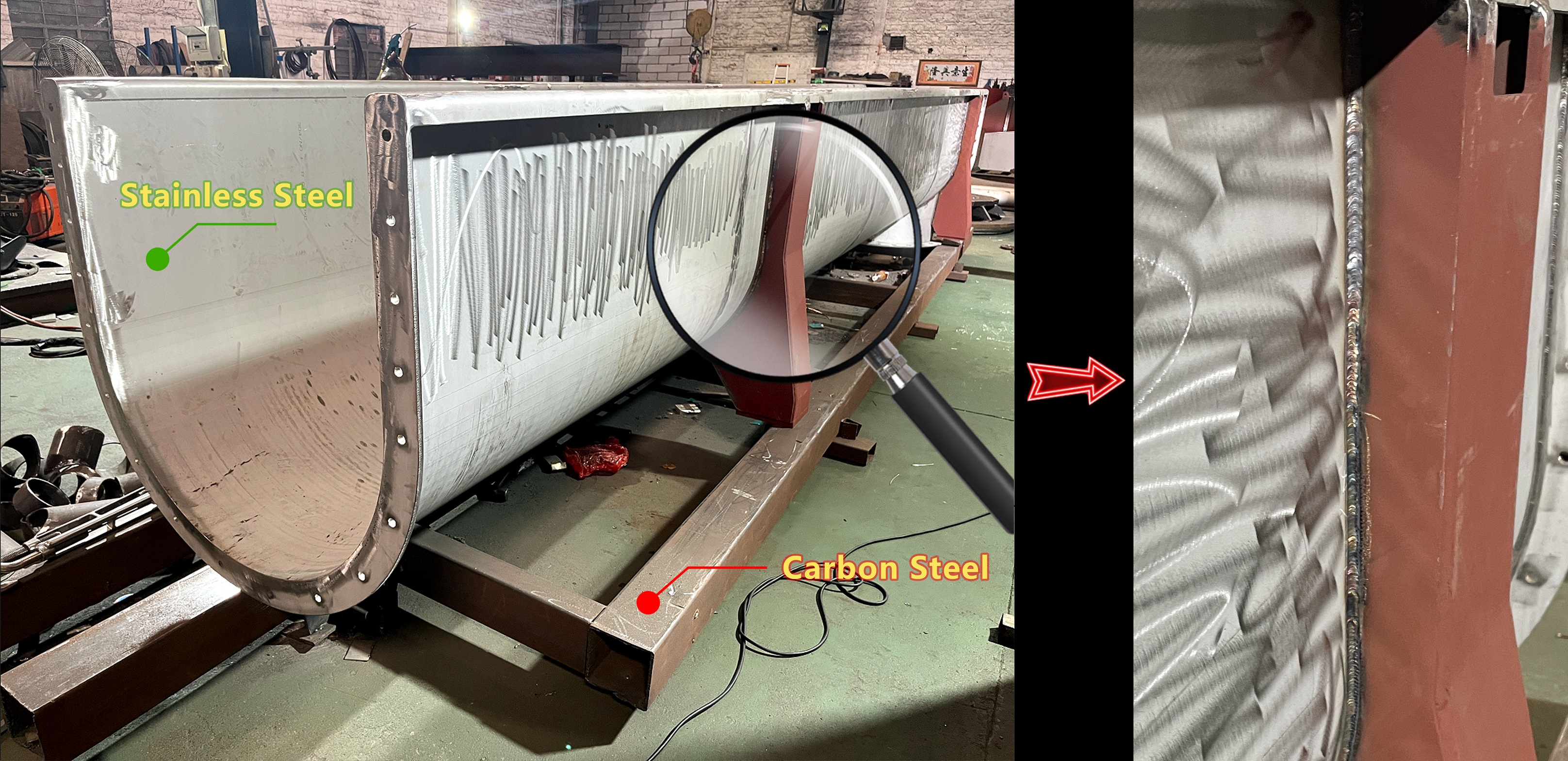

Welding dissimilar metals can create a material that is stronger than either metal alone. For example, when welding stainless steel and carbon steel, the resulting joint has a higher corrosion resistance, ideal for applications in marine environments or chemical facilities.

2. Enhanced Flexibility:

By cleverly selecting and welding different metals, engineers can create structures with a balance of stiffness and flexibility. This property is useful in applications such as bridge construction, where structures need to withstand different loads and environmental conditions.

3. Improved Functionality:

Combining metals with different properties can create parts with unique functions. For example, welding aluminum and copper can produce a joint with excellent conductivity, making it ideal for electrical and electronic applications

Applications:

1. Automotive Industry:

The automotive industry relies extensively on the welding of dissimilar metals. For example, welding aluminum and steel can produce lighter, more fuel-efficient cars without compromising safety. In addition, combining different metal alloys can create stronger and more durable frames or engine components.

2. Aerospace Industry:

In the aerospace industry, dissimilar metal welding plays a vital role in the manufacture of aircraft components. Welding titanium and aluminum alloys together can form structures with a high strength-to-weight ratio, ensuring the safety and efficiency of aircraft systems.

3. Renewable Energy Field:

Welding dissimilar metals is widely used in the renewable energy field, especially in wind turbine manufacturing. By joining steel and aluminum components, engineers can create lightweight and strong turbines that can efficiently use wind energy.

Specific Examples:

1. Welding of stainless steel to carbon steel for pipelines:

In the oil and gas industry, pipelines often require stainless steel and carbon steel to be welded together. This ensures that the joints can withstand the harsh conditions of the oil environment while maintaining structural integrity and preventing corrosion.

2. Copper-steel connection for heat exchangers:

Heat exchangers are commonly used in HVAC systems and refrigeration equipment, and the advantage is the welding of copper and steel. This combination has good thermal conductivity and strength, which can achieve efficient heat transfer and lasting performance.

Welded parts of dissimilar metals can not only make full use of the superior properties of each component material, but also be lightweight and reduce production costs, while also playing a role in energy conservation and emission reduction. Therefore, by combining metals with different properties and characteristics, engineers can create metal structural parts with enhanced strength, durability and functionality.