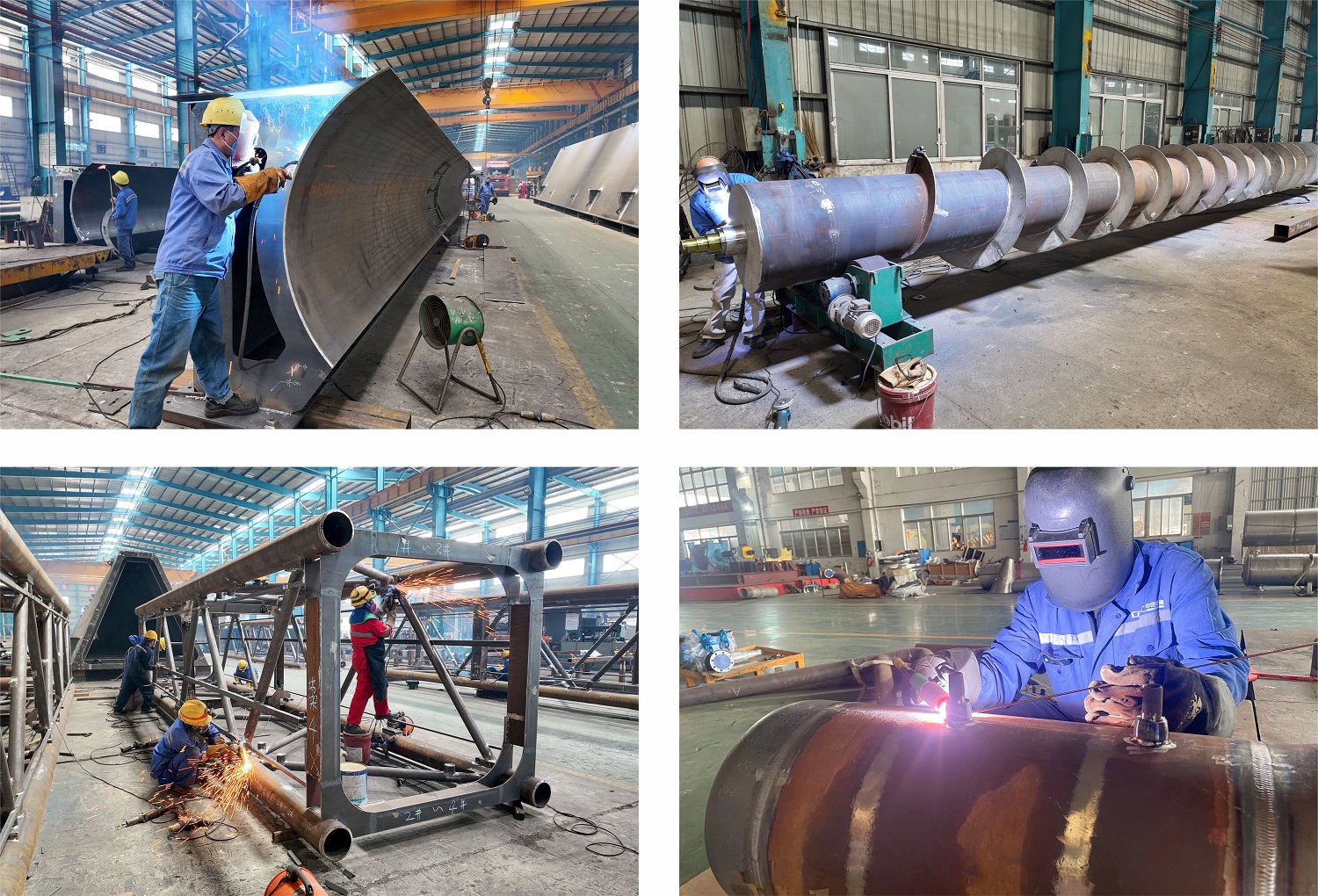

INDUSTRIAL WELDING CARBON STEEL

Steel is used across a wide range of industries for its durability, strength, and versatility. Whether you need welding services for structural components, piping systems, or

custom products, it is essential to work with a professional welding service that has extensive experience and expertise in carbon steel welding.

At Xiangxinghe, we specialize in providing top-notch carbon steel welding services. Our team consists of skilled and certified welders who have a deep understanding of

the unique characteristics of carbon steel and its welding best practices. We have state-of-the-art welding equipment and use advanced techniques to ensure precise and

flawless welds every time.

In addition to expertise in welding technology, we also prioritize safety and quality assurance in our carbon steel welding services. Our welding processes adhere to strict

industry standards and specifications to ensure the integrity of the weld and the overall structural integrity of the component or fabrication. We conduct thorough inspec

-tions and tests to verify the strength and quality of the welds before delivering the final product to our customers.

Pressure Vessels

Custom pressure vessels are used in the private sector and industry for different applications such as

storing high pressure liquids and compressed gases.

The manufacturing process of pressure vessels must be subjected to non-destructive testing, including

magnetic particle, liquid penetrant, radiographic and ultrasonic testing. These tests are followed by pres

-sure testing and internal inspection of the pressure vessel.

During the inspection, the inspector have to:

● Perform hydrostatic pressure testing

● Inspect the release valves of custom pressure valves

● Perform pressure analysis to determine if the equipment is suitable for use

● Collect thickness data on an ongoing basis

● Collect visual data, including the condition of the equipment, welds, joints, or structural links

Shipbuilding

All of our welders meet most qualification requirements.

Welding can firmly connect the parts of the ship structure, thereby improving the strength and

stability of the overall structure. The quality of welding directly affects the safety performance of

the ship, such as sealing, corrosion resistance, etc.

General equipment

We have a reputation for quality work, strong manufacturing and delivery capabilities, reasona

-ble prices and excellent customer service.

Our manufacturing range:

● Diameters typically up to 3,500 mm

● Weights typically up to 50,000 kg

● Lengths typically up to 35,000 mm

● Wall thicknesses from 1 mm to over 50 mm

Welding Technology

● Gas shielded welding

Use gas to protect the molten pool, reduce metal oxidation and improve welding quality.

● Arc welding

The heat generated by the arc melts the metal to form a molten pool. As the electrode moves,

the molten pool cools and solidifies to form a weld.

● Submerged arc welding

The heat generated by the flux melts the metal, and the flux forms a weld after the molten

pool cools.

● Laser welding

Laser welding uses a laser beam focused by a high-power coherent monochromatic photon

stream as a heat source for welding, and welding can be completed without contacting the

material.