Vertical milling machines are a common sight in machine shops. As the name suggests, these machines feature a cutting head or spindle that is vertically oriented. The spindle holds the cutting tool used to machine the workpiece. Some machines have a quill that moves the spindle along the Z-axis. Additionally, the worktable can move along the X-axis, Y-axis, and on some machines, up and down on the Z-axis.

The vertical milling machine can also function as a drill press when the quill moves vertically on the Z-axis. These machines are handy for projects where the work is on a single side, such as sectioning operations or finishing operations like beveling. There are two vertical milling machines: knee mills (also known as Bridgeport-type or turret milling machines) and bed milling machines (commonly referred to as bed mills). Each type functions differently, offering unique advantages.

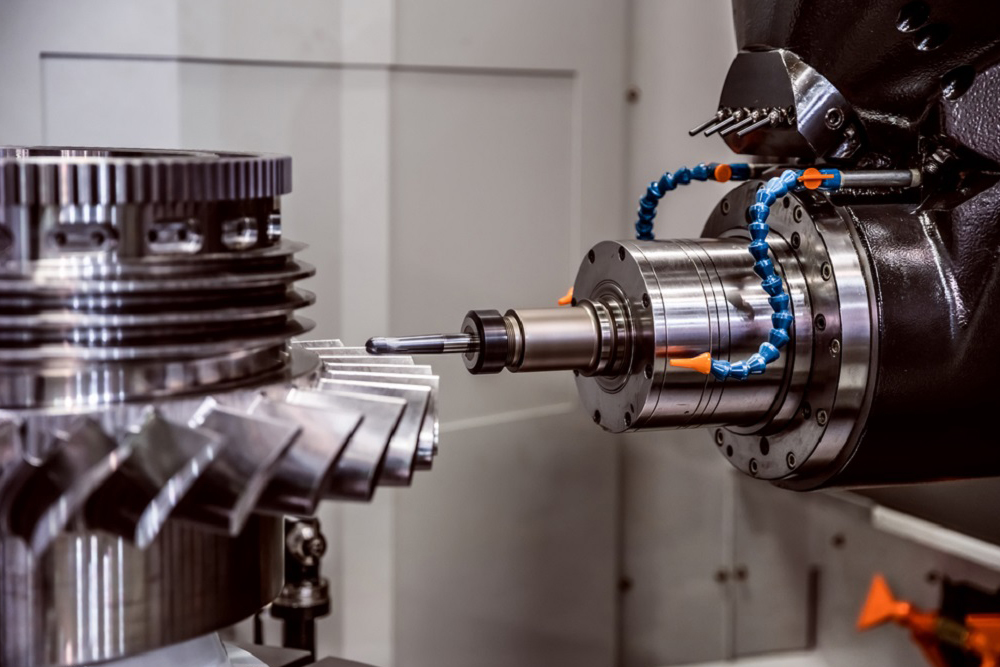

Machinists have various tools at their disposal, depending on the type of cut and material. Cutting tools can be held in the collet or directly in the milling head, and the milling head moves into the workpiece as the cutting tool spins.

In addition to milling, drills and taps can be used to create holes and internal threads. Various end mills and cutting tools are available for machining materials ranging from aluminum to titanium.

With these machines and tools, machinists are equipped to handle diverse machining tasks with precision and efficiency.

Knee Mill: The machine tool of choice for many machine shops, knee mills feature a fixed spindle. The knee moves vertically on the Z-axis, and the table moves on a longitudinal X-axis and an in-and-out Y-axis. As mentioned earlier, the rotating spindle inside the quill provides another Z-axis.

Today, many CNC mills are knee mills, and their versatility is enhanced as either a stand-alone or benchtop model. Depending on their table size, a variable-speed vertical mill has an almost infinite amount of machining uses. Many knee mills have an R8 spindle taper and a drawbar to hold collets. They are available in a single phase for home shops and hobbyists, perfect for those home machinists with one machine tool and a bandsaw to manufacture small parts. And for those parts requiring angle cuts, the milling head swivels left and right 90 degrees.

Bed Mill: The bed mill’s table does not move up and down along the Z-axis. Instead, vertical movement comes from the spindle. Unlike the knee mill, where the quill moves but not the motor, the entire head and motor of the bed mill move up and down on the Z-axis. But just like the knee mill, the bed mill’s work table travels along the X-axis and Y-axis.

Bed mills work well when large and heavy workpieces must be machined.